STOP the Waste!

Most US based manufacturing companies have, or are planning to implement lean manufacturing practices. Whether you’re producing high tech electronics or everyday widgets, companies have to focus on cost and quality in their production facilities. Originally developed by Toyota and now broadly known as “lean manufacturing”, it is a systematic approach to measuring and eliminating waste as a means to reduce cost and increase quality.

If you’re not familiar with the “lean” concept, here’s a link to find out more about it on Wikipedia. For people that are familiar with lean manufacturing, it’s time to broaden your horizons.

Lean Manufacturing on Wikipedia

“Maybe you could go to a few more trade shows”

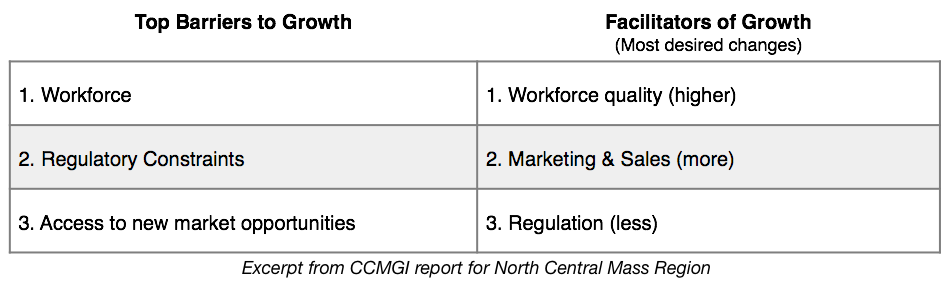

Last week I attended a meeting sponsored by MassMEP to review a report on enabling sustained growth in the North Central Massachusetts region. The report identified constraints and improvement opportunities through a series of interviews with area manufacturing CEOs. The host was a packaging company that had used MassMEP to help them apply lean principles to layout their new facility. The hosts and the majority of the audience really know about lean manufacturing. The table below highlights some of the findings from the report.

During the meeting there was a lot of discussion on how to develop a ready workforce for the types of modern manufacturing jobs available today. Area community colleges and technical universities were there to address the education requirements. Legislators were on hand to listen to concerns about regulations. But when it came to developing new markets or improving marketing and sales, there was deafening silence. Almost. One person spoke up and said there should be some funding available to help companies go to a few more trade shows.

Perhaps it’s a lack of familiarity with other disciplines, but many people very familiar with lean concepts miss the point of applying it to the rest of the business. And by the way, trade shows are not the best investment for your marketing efforts today.

LEAN: It’s not just for manufacturing anymore

At its core, “Lean” is about removing waste: wasted time, wasted effort, wasted materials. It’s about focusing on the right things. The things your customer cares about and is willing to pay for. Lean thinking has moved well beyond the factory floor. Today it’s being applied to software development, technology start-ups and even marketing & sales.

“The Remedy” by Pascal Dennis published in 2010 is subtitled “Bringing Lean Thinking out of The Factory to Transform the Entire Organization.” Here is an excerpt from the preface:

Because that’s where the opportunity lies. Upstream—in marketing, design, and engineering. Downstream—in distribution, sales, and customer service. These, together with health care, service, and government, are Lean’s frontier. I am less and less a factory rat.

Every core Lean principle applies outside the factory. But business processes are harder to fix.”

The author uses a folksy approach to the subject by using fictitious characters and company names. Through these examples he brings the principles to everyday experiences ranging from a Greek diner to hospital emergency rooms. The book is filled with lean methodology, terminology and process improvements. It’s worth reading if you’re curious about how lean can be applied more broadly.

“The Remedy” on iTunes

“The Lean Startup”

Literally applying lean manufacturing directly to other areas may not be the best approach. Eric Ries uses lean principles and adapts them in his book “The Lean Startup” published in 2011. He shares his experiences built over ten years of starting businesses, failing, and learning from the mistakes. Eric applied lean thinking to startups to minimize capital requirements and maximize learning. He borrowed and adapted techniques from lean manufacturing to make things measurable. Measuring something is the first step toward improving it.

Applying lean thinking to product innovation means experimentation to find new product failures early–and focusing on the features and concepts that customers really value. This is in stark contrast to the traditional “waterfall” development approach where all market and technical requirements are defined up-front before development begins. Have you ever had a new product fall flat after it launched? At that point you have already invested 100% of the time, effort and cost into the product. What if you figured out the problem after only 5% of the investment? The rest could have been spent finding and developing a winning product.

In the short time since it was published, “The Lean Startup” has changed the way entrepreneurs and venture capitalists think about the business of creating new businesses. It’s being applied around the world–including right here in the Boston area. I recommend adding it to your summer reading list. It’s available on iTunes and Amazon.

“The Lean Startup” on iTunes

Eliminating Waste: It’s about Measurements and Process

The big take-aways from “The Remedy” and “The Lean Startup” are using a systematic approach to identifying and eliminating waste. The principles apply broadly across the entire organization–whether you’re a technology startup, a small-to-mid sized manufacturer, or a global enterprise.

From my background in engineering and control, I know you can’t improve what you can’t measure. It’s just as important to make sure you are measuring the right things. In any system, each step must make it easier for the next. It’s just as true in marketing, product development and sales as it is on the factory floor. I encourage all of us to use “lean” principles to stop wasting time, effort and expense in our own businesses.

Written by:

Jay Galasso, Managing Director

B2B Growth Partners